History

The process of murrine art glass incorporates mosaic techniques originated over 3,000 years ago, prior to the discovery of glass blowing. Mosaic glass peaked around the first century BC/AD, about the time when blown glass objects first made their appearance. Shortly thereafter, the mosaic art form quickly fell out of favor.

It wasn’t until late in the nineteenth century that a revival of the technique surfaced in Italy. It was in Murano, Italy where the process was developed and refined along with milk glass, crystalline glass, enameled glass, and aventurine (or glass with threads of gold).

The Creative Process

An Abbreviated Description in Four StagesSTEP ONE: DEFINE THE PROJECT

The artist developed his award winning Colorbar Murrine Series by combining the hot glass technique perfected in Italy with the fused glass process, also known as “kilnforming”. The artist’s first step in creating an art glass piece for the Colorbar Murrine Series is to plan ahead by defining the details. Settling on the type of project is key. For instance, the final artwork may be a wall piece, a vessel, a pedestal piece or perhaps a sculpture. Predetermining the desired colors, pattern and design is essential. Equally important is specifying the size, and then estimating the required number of murrine to complete the project.

Answering these questions greatly assists in determining the scope of the project, including how much time to budget and what resources to secure.

STEP TWO: CREATE CANE

Once the project has been defined and resources secured, it’s time to move on to the next stage: creating cane, or as the artist calls them, “colorbars”. As with any fused glass project, art glass that has been tested to be compatible during the firing process is thoughtfully selected. There are several techniques to creating cane, but for the Colorbar Murrine Series, the art glass is cut, prepped, arranged and then placed in a kiln where it is carefully heated to a temperature that causes the glass to melt, or fuse, together. The glass then goes through a scheduled, multi-step cooling process. The gradual drop in temperature is carefully controlled to remove any internal stress created from the initial heating of the glass. This cooling process is called “annealing the glass”.

Upon reaching room temperature, the glass can then be removed from the kiln. The end result, is creating cane, or colorbars.

STEP THREE: MAKE MURRINE

After the colorbars have been created and removed from the kiln, they can be prepped for the next step, making murrine. Depending upon the complexity of the final project, however, the colorbars may be further manipulated to produce an even more intricate design. For example, several colorbars could be combined, re-heated and then pulled, or stretched, to form a new colorbar. This part of the process can be achieved either by using the same kiln, a glory hole or via an adapted kiln for a Vitrigraph pull. The cane resulting from this last technique are usually more rounded or rod-like and often times vary in size, so they are typically reserved for the artist’s Colorcane Murrine Series.

In either case, once the final colorbar or colorcane has been created, murrine making commences! As practiced in Murano, the cane is cut or sliced into many small pieces, called “millefiori” or “murrine”. Since heating the glass is not necessary for murrine making, this part process is often times called “cold working the glass”.

STEP FOUR: THE FINAL FORM

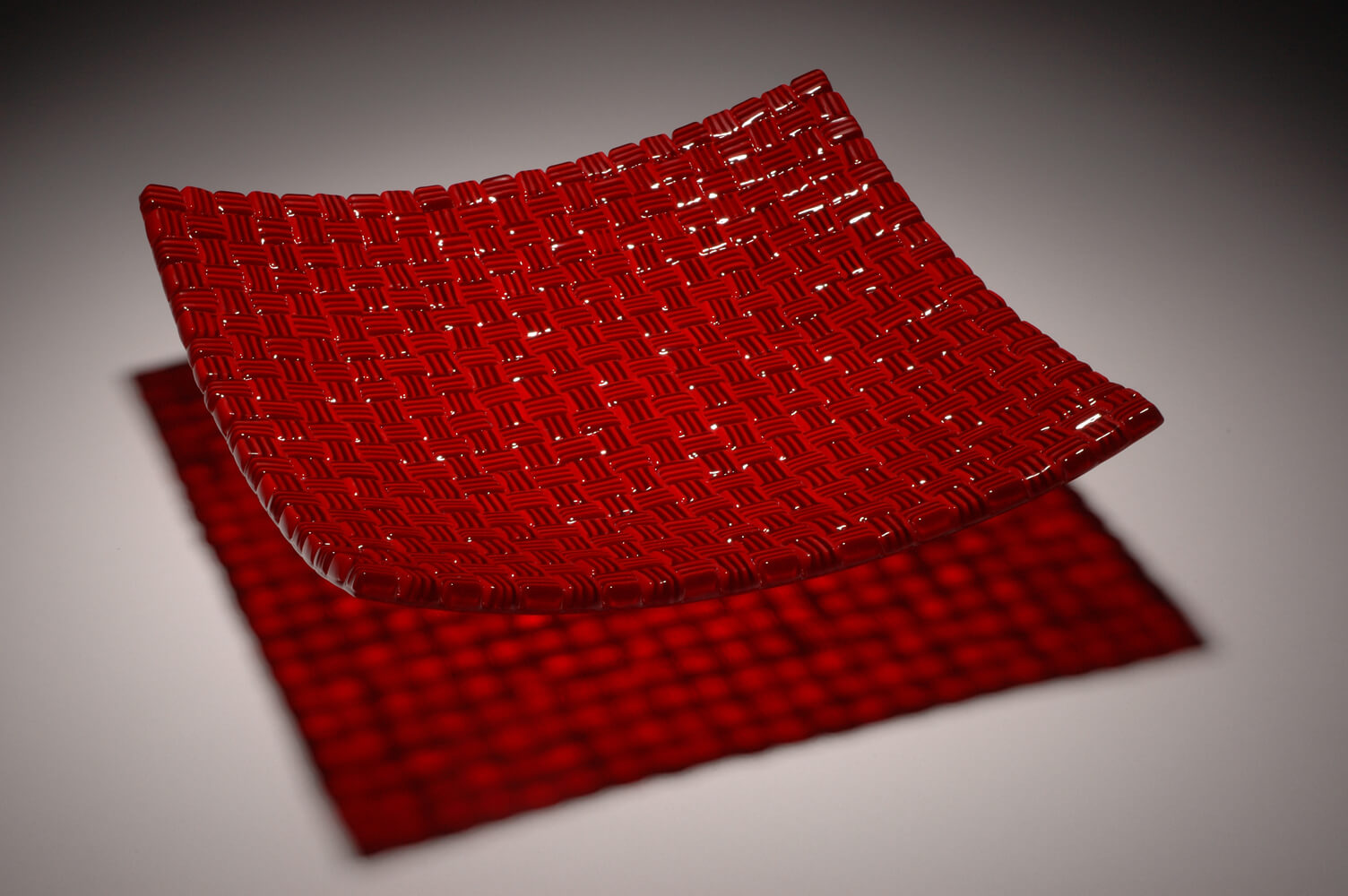

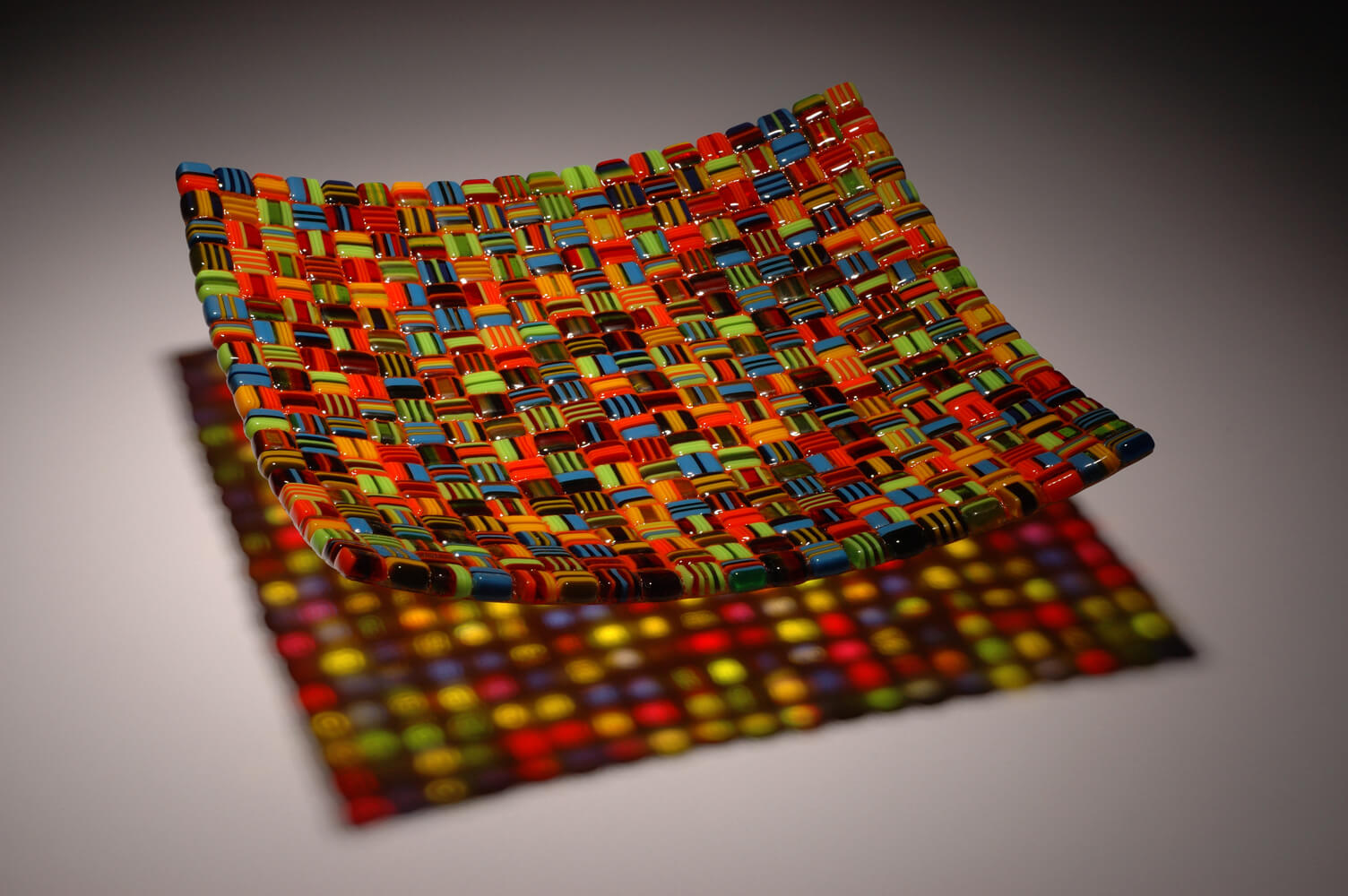

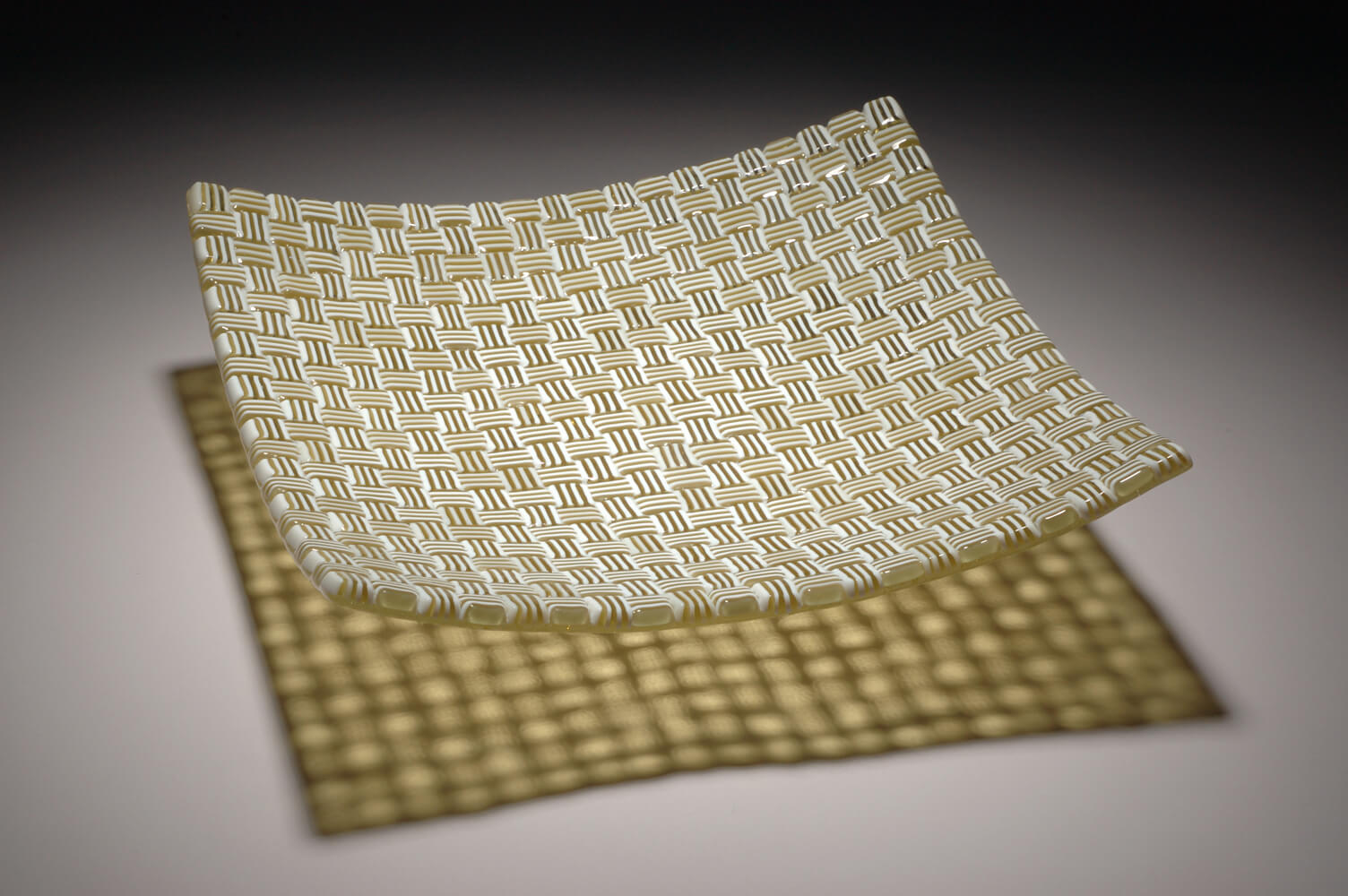

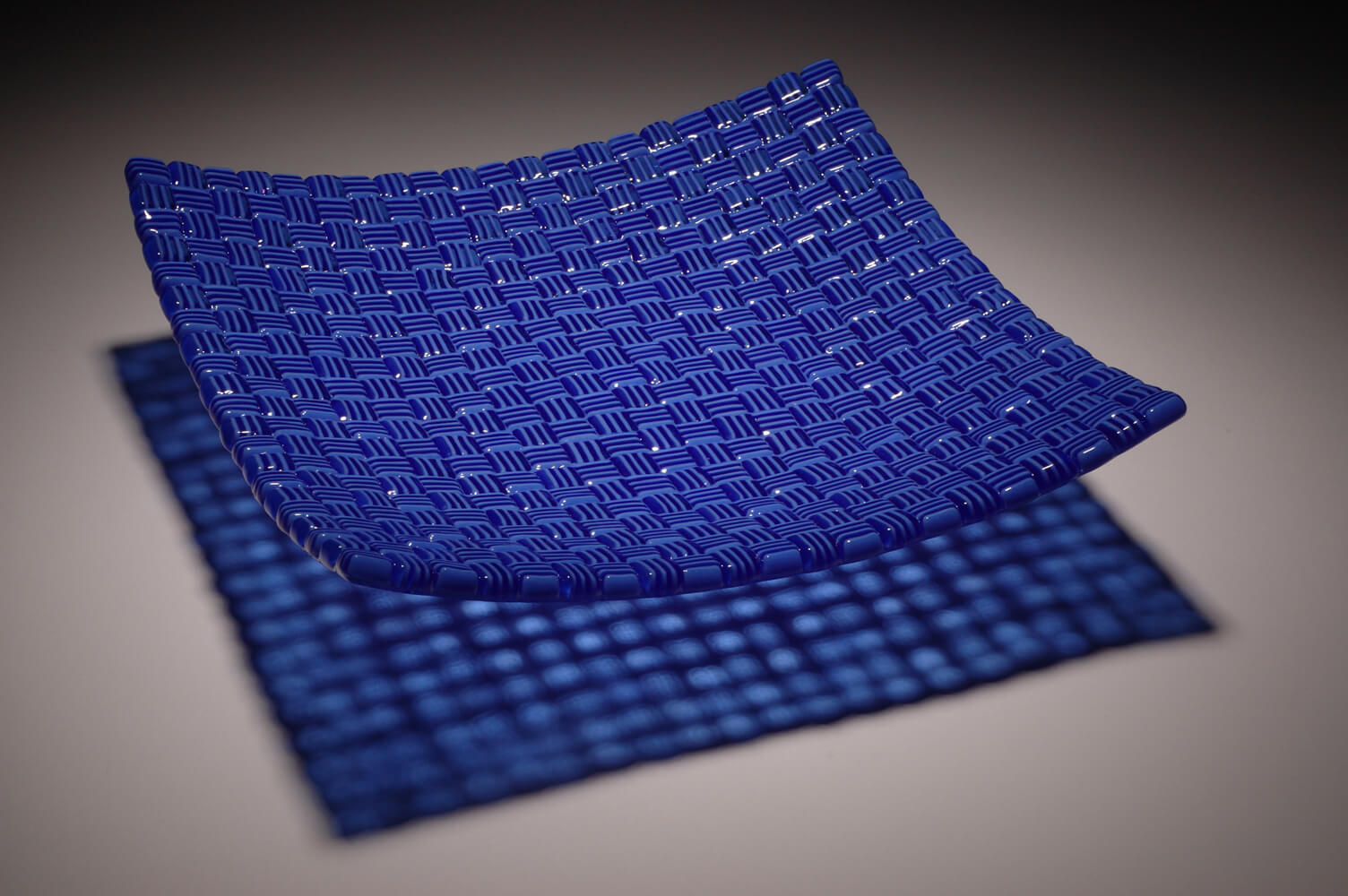

Referring back to the initial project plan developed in Stage One, each murrine is then meticulously arranged by hand into the desired design or pattern. Multi-color Colorbar Murrine projects, such as Summer Salsa Shallow Vessels, are created with murrine sets that can contain well over 450 color combinations. That’s quite a bit of cane creating and murrine making! To help insure proper murrine selection during assembly, all murrine in the DC Art Glass studio are stored in separate containers, sorted by cane, then by color scheme and often times by date. Once all the murrine have been placed and the desired design or pattern has been achieved, the arranged murrine are returned to the kiln for yet another firing. This time, for the purpose of merging the individual pieces back into one single piece of glass.

Following a proper annealing and once at room temperature, the art glass piece may be removed from the kiln and prepped to become a wall hanging or pedestal piece. Alternatively, the art glass may be integrated into another project or returned to the kiln or glory hole to be transformed by heat into a vessel or sculpture.

EVOLUTION

The Colorbar Murrine Series was originally designed as a sculptural collection, mainly consisting of shallow vessels. Since its inception, the series has evolved to include wall panels, pedestal pieces (panels with stands), and lighting (sconces). To date, designs have incorporated up to 20 color selections, over 2,000 individual handmade murrine and over 425 murrine designs. No two multi-color pieces are exactly the same.

Color Selections

Individual Murrine

Murrine Designs

FAQs

What are the differences in surface finishes?

Most shallow vessels, pedestal pieces and wall panel designs can be created with a gloss or a matte finish. The matte finish requires extra steps that include sandblasting and re-firing the glass. For this reason, the type of finish must be determined prior to starting the project.

Are some pieces ceramic, or are they all glass?

With the exception of hardware used to hang or stand the artwork, all Colorbar Murrine pieces are 100% art glass. Each piece has been created from glass that has been carefully selected and specifically designed to be compatible during the firing process.

In some cases, additional techniques have been applied to produce art works that have an alternate surface texture. For example, a “matte” surface can be obtained by sandblasting and re-firing the glass. This technique results in a satin-like surface texture that often times can be mistaken for stone or ceramic.

Are Colorbar Murrine pieces signed?

All CMS pieces are handmade in the DC Art Glass Studio and signed by the artist. Due to the nature of the design, the signature is engraved on the reverse side. In most cases, glass panels signatures are located on the back, lower right corner. Shallow vessels are signed nearer to the back center. The color of the glass may affect the visibility of the engraving.

How is the glass cleaned?

It is recommended to use a clean, soft, lint-free cloth to gently wipe the glass surface. The cloth may be dampened with water. Before wiping, be sure to inspect both the cloth and glass surface for any tiny objects that could cause the glass to scratch. Always make sure the glass is secure before wiping. Never use harsh chemicals or grainy cleaning solutions. Avoid the dishwasher!

Are the displayed colors and sizes accurate?

Each Colorbar Murrine piece is individually handmade by following a detailed, multi-step process. While every attempt is made to remain consistent, it is common of handmade kilnformed glass objects to have slight color shifts, incidental size fluctuations and tiny “champagne” bubbles. By design, no two multi-colored Colorbar Murrine pieces will be exactly the same.

How are the wall panels hung?

Wall panels come standard with a French cleat hanging system. In most cases, the bottom half of the cleat is attached to the wall with screws while the top half has been attached to the back of the panel by the artist. The panel then rests on the bottom cleat attached to the wall. For opaque panels, the French cleat cannot be seen from the front, creating a floating effect.

As a second option, an aluminum peg “stand-off” hanging system is available (for an additional fee). The “stand-off” hanging system uses up to four aluminum pegs per panel which, when hung, are visible from the front.

Hanging instructions are included with each purchase.

Do pedestal pieces include the stand?

Pedestal pieces include the metal stand. Unless otherwise noted, the given dimensions are of the glass panel. They do not include the height of the stand.

How do I protect my furniture?

Vinyl bumpers are either included in shipping or are already applied to the bottom of each vessel. The bumpers help keep the art work secure and, at the same time, protected the underside of the glass and surface of the countertop or furniture.